PRODUCT Catalogue

1] Specialty Rubber Raw Material

Firestone®Solution SBR

Firestone® SSBR has narrow molecular weight distribution and customizable styrene/vinyl contents. It is ideal for rubber applications such as tires, flooring and conveyor belts, which require superior abrasion resistance, wet traction and low heat generation.

Benefits:

- Linear structure provides superior dimensional stability during extrusion.

- The Tin (Sn) functional end groups help carbon black dispersion.

- Use high viscosity naphthenic oil for better dynamic property.

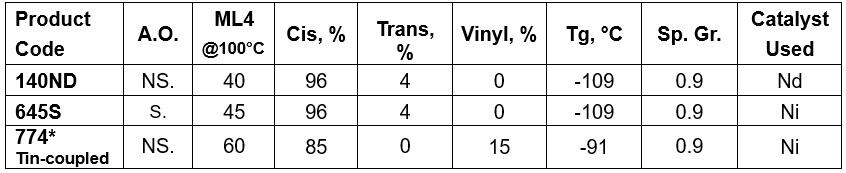

Firestone® Polybutadiene Rubber

Firestone®Solution-polymerized polybutadiene rubber (PBR) has the major application in Tire and Industrial Rubber Application:

Firestone® PBR is available in three grades: high Cis at 96 percent for tires and rubber goods.

Benefits:

- A wide range of Mooney viscosities.

- Excellent abrasion resistance.

- Good processability recognized by leading global tire manufacturers.

Liquid Natural Rubbers

The DPR products are liquid natural rubber (NR) with low molecular weight. When added at levels of 5 to 20 phr, DPR improves blend consistency, reduces the risk of scorching and minimizes mixer power consumption. DPR is compatible with both NR and a variety of synthetic polymers such as IR, EPDM, PBR, SBR and CR

Benefits:

- Improve dispersion of rubber and polymer compound in final processing.

- DPR is not processing oil. DPR cures by the same mechanism as NR.

- It becomes part of the polymer matrix and remains non-fugitive. This extends the service life of finished products.

FSC certified NR

Multiwinners provides FSC certified natural rubber and Low Allergen Deproteinised Natural Rubber (DPNR). Natural rubber is considered as a sustainable material. In today's environmentally conscious world, reducing carbon footprints and using sustainable materials have become increasingly important; the FSC certified natural rubber and low allergen natural rubber provided by Multiwinners can meet this requirement.

Advantages of Low Allergen Natural Rubber:

- Low Allergen Natural Rubber has less than one-fifth the protein content of regular natural rubber.

- Maintains high tear, stretch and resilience properties of natural rubber.

- From renewable resources.

- Low CO2 emissions (only 16% compared to synthetic rubber).

Brown Factice

Brown factice is vulcanized unsaturated vegetable oil. Unlike processing oil, factice is an elastic material with 3-D network structure that can mix with rubber compound and improve the dimension stability of cured products.

Benefits:

- Maintain compound durometer and flexibility over time and temperature; permanent softener for lower hardness rubber goods.

- Absorb liquid compounding agents such as oil and plasticizer; prevent tacky/bleeding.

- Reduce die swell and improve dimensional stability.